When it takes three years of training to be able to professionally write an ironmongery schedule, you know you’re dealing with a sector with detail at its core. FIS technical manager Joe Cilia talks to industry experts to highlight the key aspects to consider in an ironmongery specification.

“Don’t value engineer the hinges,” commented Wayne Harris, managing director at architectural ironmongery supplier Harbrine. “People think they are saving money, but this is often a false economy and you frequently see grease dribbling out of hinges that are simply not fit for purpose.

“The hinges fail and the door drops and becomes damaged. It’s a costly mistake, especially in high-traffic areas such as schools,” explained Mr Harris, adding, “Typically, ironmongery will account for 1 per cent or less of a building’s cost, so any savings are likely to be minimal.”

Franz Lorenschitz, marketing manager at Allgood, which supplies architectural ironmongery and doorsets, said: “We see it on a regular basis where a contractor looks to change the specification due to cost and then runs into additional costs because the so-called cheaper alternative didn’t allow for something important.”

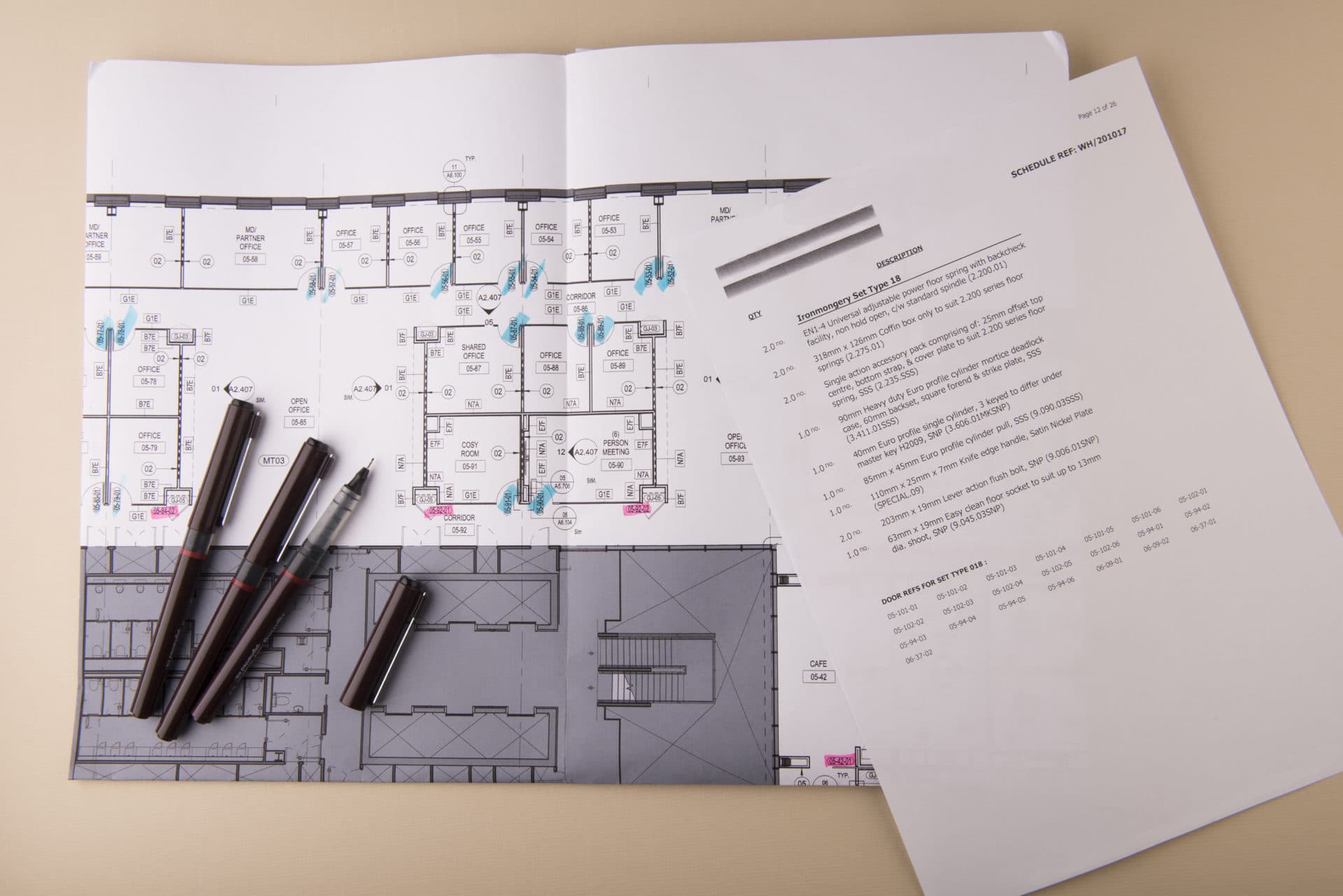

Writing an ironmongery schedule is a learned profession. “It’s one that takes three years,” said Douglas Masterton, technical manager at the Guild of Architectural Ironmongers (GAI), which runs and administers the GAI Diploma.

Paul Smith Dip GAI, UK sales director at Allgood, said: “People who achieve the Dip GAI are trained to ensure the correct ironmongery is specified, taking into account the performance of the door and its size. When it comes to ironmongery specification, a well-planned and executed process saves time, cost and resources.”

Michael Skelding from the Door and Hardware Federation (DHF) said that one of the biggest issues he sees concerns the correct specification, installation and then maintenance for door closers. “Generally, people are not aware that there are different strength closers and some can even be adjusted and provide a soft close to stop doors banging shut,” Mr Skelding said.

Mr Harris of Harbrine added: “There is also the issue of automatic entrance systems – sometime referred to as ‘wiremongery’. It’s where ironmongery needs the services of an electrician to make it all work.”

This was echoed by Mr Masterton, who said he had seen issues where Approved Document Q: Security in dwellings, needed to be met and people were not fully up to speed on what was needed to meet the requirement. “This is another good reason to use a trained person to write the specification,” commented Mr Masterson. “For example, automatic doors need to have finger-trap protection to meet EN 16005, yet they may fall foul by not including it in the package.”

New technical advances and the rise of high-density residential developments has seen an increased use of pocket doors. These are doors that slide and therefore save space usually taken up by the swing arc by using a void in the solid, or even glass, partition to hide the open door.

“These pocket doors are being used in a lot of schemes,” said Jonathan Woodcock, an industry specification adviser working with ROB, a door systems design and manufacturer. “We are working with architects to ensure some of the tall and heavier doors can be installed with an integrated frame that will carry the door without distorting the single skin of plasterboard on either face, and working out how the tracks can be maintained without having to open up the walls.”

So, before you look to shave a bit from the cost by value engineering the hinges or think ironmongery schedules are easy to do without training, think again – it could cost you more than you might ever save. As ever, talk to the experts, every time.

Joe Cilia

FIS Technical manager

joecilia@thefis.org