In March last year, an All-Party Parliamentary Group (APPG) report highlighted the dangers and lack of awareness around silica dust. Here, H&S practitioner, David Cant, of Veritas Consulting, explains the steps architects and designers can take to remove the risk of exposure to silica dust on site.

In the 1970s, the use of asbestos – once considered a miracle construction material – nosedived when its potentially fatal effects were revealed. Widely used in multiple applications thanks to its tensile strength and impressive insulating effects, the material was banned in the UK in 1999 for its tendency to cause lung diseases and cancers when inhaled.

Though existing asbestos remains a threat during refurbishment and demolition projects, more than 20 years on from its ban in the UK, designers and architects are now able to specify much safer materials, with the awareness of asbestos dramatically reducing exposure.

But asbestos is not the only worry for those who specify materials and take responsibility for project planning. Recently, concerns have been raised about another threat to the health and safety of those working in construction: silica dust.

What is silica?

Silica is a naturally occurring substance in common building materials such as concrete, bricks, tiles and mortar. When left alone it is perfectly safe, but when these materials are drilled into, cut, or otherwise fractured, the naturally occurring silica becomes respirable crystalline silica (RCS). Workers near to the materials when this fracturing take place can inhale the airborne dust and, over time, potentially develop silicosis, an untreatable but entirely preventable lung disease.

Silicosis occurs over several years of exposure to silica dust which puts construction workers and those in similar roles, such as demolition and quarrying, at extremely high risk. Early symptoms include a persistent cough and shortness of breath. It can ultimately be fatal due to respiratory failure.

The next asbestos?

In March 2020, an All Party Parliamentary Group Report (APPG) on the dangers of silica was published in partnership with B&CE, entitled Silica – the next asbestos? In the report, the government was urged to take the threat of silica seriously, and it highlighted the extensive lack of awareness of silica and silicosis in the UK, particularly in the construction industry.

The report made several recommendations to minimise the risk of silica dust to those in construction and beyond. These include:

• making silicosis a reportable condition under RIDDOR, alongside conditions such as carpal tunnel syndrome, asthma, and tendonitis;

• creating industry awareness through targeted programmes;

• screening for those exposed to RCS; and

• lowering the workplace exposure limit to bring RCS into line with other developed countries.

The Health and Safety Executive has warned that silica is the biggest risk to construction workers after asbestos, with around 600,000 workers having been exposed in the UK.

What designers can do

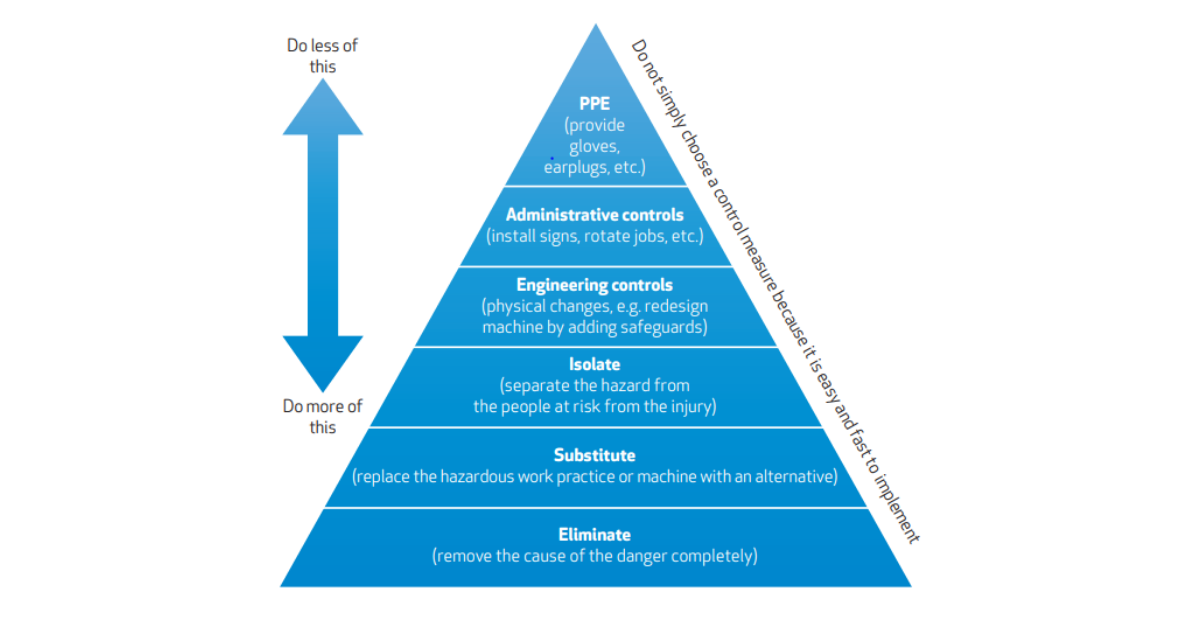

The responsibility to minimise silica exposure runs across the entire construction sector, but architects and designers have an especially important role to play. The APPG report states that designers, when planning construction projects, should do everything in their power to prevent RCS exposure. In the first instance, the potential of exposure should be designed out entirely wherever possible. Stating that there is no ‘acceptable’ level of RCS exposure, the report suggests that designers should aim to ensure cutting and fracturing is done offsite, at specialised facilities with high levels of controls, such as exhaust ventilation, water suppression and professional respiratory equipment.

The report also says if offsite manufacture cannot be achieved, then cutting on site should only be done with the highest quality controls in place. Many designers are already aware of the risk of RCS and, as such, specify offsite manufacture – but too many projects utilise on site cutting to reduce cost and time involved. Furthermore, potentially life-saving PPE such as professional grade masks are overlooked in favour of less expensive options, despite being zero-rated for VAT and tax deductible.

Though these tactics may save money in the short term, they can be far more costly in the long run, both in human terms and possibly financial, if it is found that the responsibility to protect workers was shirked.

Jim Shannon MP, Chair of the APPG, said: “The inquiry has given us real insights into the outstanding work carried out in the construction industry and the hazards that are too often part of everyday life for those who work within it. We hope that the outcomes of the report will assist the Health and Safety Executive, the Government and the construction industry to protect its workforce from preventable injury and illnesses.”

Like asbestosis, silicosis is terrible but ultimately preventable through awareness and safe, thoughtful planning. Designers and architects, as well as those with health and safety responsibilities throughout the life of any project should be aware of this risk and take all necessary steps to lessen its impact.