James Parlour, FIS Technical and Vetting Manager, looks into the specification of operable walls, the unique challenges, and the guidance provided by FIS and its members.

The specification of operable walls unlike other static non-loadbearing partitions can offer some unique challenges that are often not well communicated by published standards and norms. Whilst individual manufacturers within FIS membership can and should be referred to for assistance in ensuring accuracy in detailing and representing the performance capabilities of a product, there will always be a place for independent guidance that advises on the generic requirements of a product and the pitfalls involved in producing a robust specification.

What is missing?

Operable walls lack a single dedicated product standard that can easily be referred to for all relevant performance criteria or descriptions of best practice, including references to purpose-designed test methodologies. They also lack a product standard that carries UK designated status that would mandate a Declaration of Performance (DoP) with defined essential performance characteristics and metrics.

Where they sit: BS 5234-1:1992 Partitions (including matching linings)

Instead, operable walls sit within the scope of BS 5234-1 which covers all non-load bearing partition types. In this standard, operable walls are only briefly referred to as one type amongst many and whilst some typical performance characteristics of an internal wall still apply, others such as fire and smoke resistance apply only under very specific circumstances. In other regards the inverse is true, and operable walls have considerations that do not apply to other non-loadbearing internal walls. The most significant is the need for an operable wall to load its supporting structure (usually by suspension).

A unique challenge

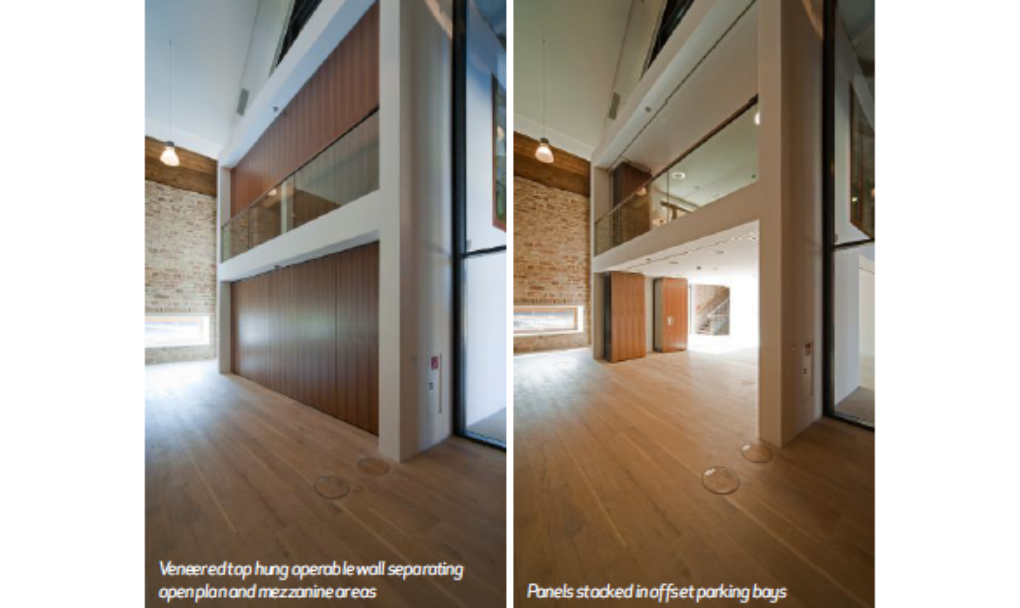

The suspension method for an operable wall represents a fairly unique challenge as, unlike some other suspended elements of construction, the load to the supporting structure is mobile. Perhaps more importantly, the product can allow for stacking of panels during operation such that the weight of almost the entire system can load a single point anywhere along the head track at one time (not just the designated parking areas). Early engagement here is critical because these design loads could be significantly higher than anticipated. In addition to contacting the manufacturer for assistance with weights and compatible detailing, the loading to the structure will need to be properly assessed and calculated by the “designer” or “principal designer” with appropriate demonstrated competency before appropriate suspension methods and top fixings are selected to suit the application.

FIS, in conjunction with its membership, is currently developing a new Specifiers Guide to operable walls that will sit alongside a suite of others that already cover the specification of drylining, demountable partitioning, suspended ceilings and steel framing system. The new guide will be published early in 2024 and will be downloadable by visiting:

www.thefis.org/membership-hub/publications/specifiers-guides