Joe Cilia, CoChair PFKG and FIS Technical Director representing the finishes and interiors sector discusses the problems with how compartment walls are constructed and what you should consider answering this problem.

Overview of the problem

Compartment walls constructed from drylining are often considered to all have generic fire resistance performance, yet the reality is that drylining used to provide compartmentation should be designed as a complete system including the doors and any penetration to avoid costly remediation where the installations have no overall evidence of compliance.

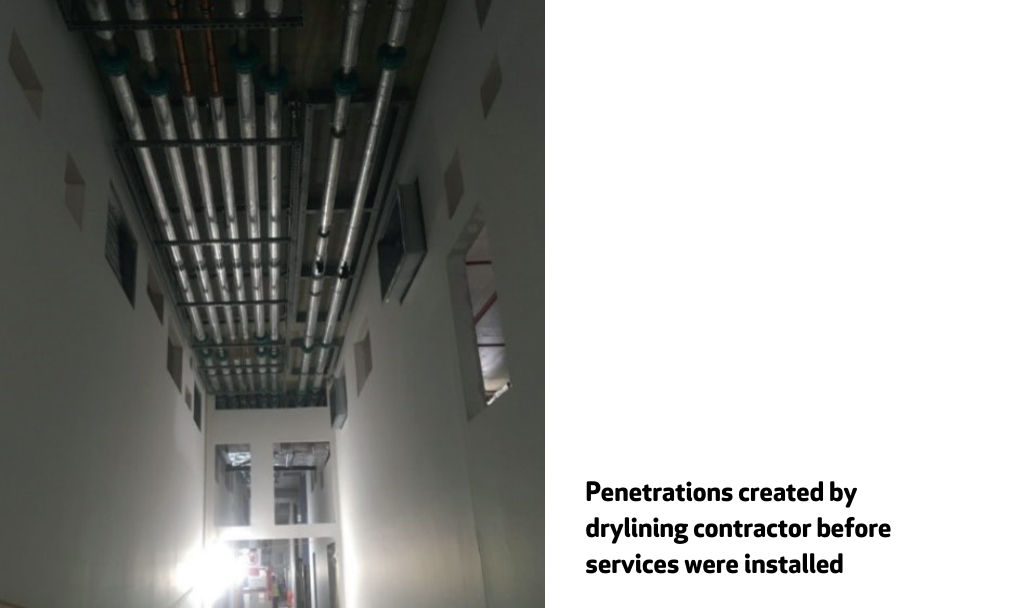

Compartment walls constructed using steel studs and plasterboard facings have test evidence for systems able to meet the requirements of Approved Document B with systems up to two hours and even more, they are also required to meet other parts of the building regulations and industry requirements such as acoustic performance, building movement and robustness; in all cases they are tested imperforate yet in most cases we perforate them and still expect them to perform.

These perforations include:

• Doors

• Pipes

• Cable trays

• Wires

• Ducts

• Fire dampers

• Smoke control dampers

• Structural beams

The issue is that these elements can be treated in isolation on the assumption that all drylining is constructed and detailed the same across the industry and that the test evidence used by the systems perforating the wall align, which is not always the case.

Some simple examples of this include the classifi cation of walls (also known as supporting structures) where a standard wall type C might be used because it will give the best overall performance to ensure it won’t fail in a damper test yet the damper may be installed in a wall classified as A meaning in that instance that the installation would be non compliant. The same would be true where an asymmetric construction (Shaftwall) is specifi ed but the test evidence uses a standard symmetrical construction.

The answer is to consider walls as a system in the same way as we look at fire door sets, fire curtains, fire ducts, etc, that is to say, the whole fire wall including what penetrates it and its interface with the other building elements.

The Passive Fire Knowledge Group (PFKG) has been formed to address issues such as this and then share the outcomes at www.pfkg.org