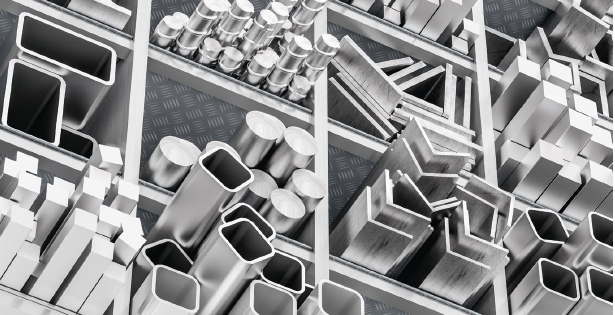

Aluminium is a popular choice of material for fit-out specialists involved in the installation of drylining, suspended ceilings and partitioning systems.

There is a good reason why aluminium is favoured by specialist installers tasked with the fitting of refurbishment of commercial and public buildings – it takes comparatively little energy to produce, is adaptable and easily recyclable.

Neil Miller, Sales and Marketing Director at FIS supplier member, QIC Trims, a UK supplier of aluminium trims and associated products, considers some of the other benefits of this increasingly precious metal for the fit-out sector.

The trims supplied by QIC provide a smart, durable finish for a range of fit-out applications including drylining, suspended ceilings and glass partitioning systems. The lightweight material allows for the trims’ easy handling and transportation, resulting in a cost-effective installation that will supply any office or interior commercial space with a sleek, contemporary look that will stand the test of time.

Recycle and repeat

QIC Trims is committed to reducing its impact on the environment, and aluminium with its superb recyclability, is key to these sustainable ambitions. Recycling the material saves 95% of the energy required to manufacture aluminium from raw materials. Furthermore, material left over from the aluminium production process can be melted down and used repeatedly. Aluminium’s adaptability is another of its properties – it enables QIC Trims to manufacture its standard products and bespoke curved trims to suit a particular radius or design. This benefit comes into its own in the production of transition trims for ceilings, with their aluminium composition allowing the manufacturer to incorporate a reveal detail between ceiling membranes.

This provides the ceiling with clean lines and a finish befitting an interior requiring a contemporary, corporate look.

Manufacturing supplies which meet demand

QIC Trims are pre-formed using the extrusion process to produce trim to required lengths and shapes. This process is ideal for a material such as aluminium; it involves channelling heated aluminium through a die at partner extrusion mills, which gives QIC control over when and where the trims are manufactured and how much is produced.

One third the density of steel, postmanufacture aluminium is easy to cut onsite and mitre. It means any last-minute design alterations can be incorporated without causing significant impact to the works programme in terms of delay and cost. Another of aluminium’s credentials as an ideal material for the fit-out sector is its resistance to rust and other corrosive elements. This is due to its natural formation of a thin oxide layer, which counteracts the threat of further, damaging oxidation. Aluminium has no rivals as a suitable metal for a wide-range of interior commercial applications. Its compatibility with the extruded manufacturing process should see its use increase, rather than diminish in the years to come. And that can only be considered a good thing. Because in terms of its sustainability, cost-effectivity, design and usability, aluminium is pure gold for the fit-out industry.